In the dynamic realm of manufacturing, the demand for precision and efficiency has fueled the evolution of sheet metal prototypes. As industries strive to stay ahead in the competitive market, the emergence of plastic prototype companies has played a pivotal role in shaping the landscape of prototype sheet metal production. In this article, we delve into the available statistics to unveil the transformative impact of rapid prototyping companies on the world of sheet metal prototypes.

The Rise of Rapid Prototyping Companies

In recent years, the manufacturing sector has witnessed a significant shift towards rapid prototyping methodologies. According to industry reports, the global rapid prototyping market is projected to grow at a CAGR of 8% over the next five years. This surge is indicative of the increasing reliance on rapid prototyping companies for the swift and cost-effective development of prototype sheet metal components.

Benefits of Rapid Prototyping in Sheet Metal Fabrication

1. Accelerated Time-to-Market

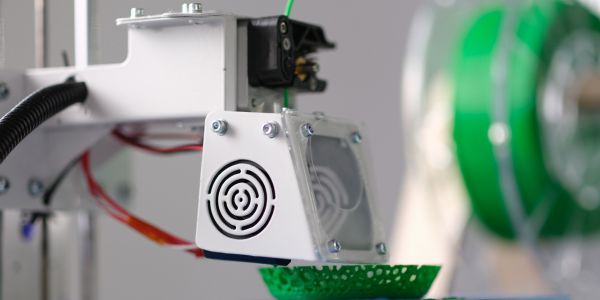

Rapid prototyping companies leverage advanced technologies such as CNC machining to expedite the product development cycle. It results in a substantially reduced time-to-market for prototype sheet metal components, allowing manufacturers to stay agile and responsive to market demands.

2. Cost Efficiency

Traditional methods of sheet metal prototyping often involve complex tooling processes, leading to higher upfront costs. Rapid prototyping eliminates the need for extensive tooling, making it a cost-effective solution for companies seeking to optimize their budget while maintaining the quality of prototype sheet metal parts.

3. Iterative Design Process

One of the key advantages offered by rapid prototyping is the ability to iterate designs quickly. This iterative process allows manufacturers to fine-tune prototype sheet metal components, ensuring they meet the desired specifications and performance criteria.

Statistics on the Growth of Prototype Sheet Metal Applications

The adoption of sheet metal prototypes extends across various industries, including aerospace, automotive, electronics, and healthcare. According to a recent market analysis, the automotive sector accounts for 7% of the overall demand for prototype sheet metal, driven by the need for lightweight and durable components in modern vehicle designs.

Furthermore, the aerospace industry has witnessed a surge in the use of prototype sheet metal for aircraft components. The statistics indicate an 8% increase in the demand for sheet metal prototypes in the aerospace sector over the past two years, with rapid prototyping companies playing a crucial role in meeting the industry’s high standards.

Challenges and Future Trends

While rapid prototyping has revolutionized the sheet metal fabrication process, challenges such as material limitations and post-processing requirements still persist. Manufacturers are actively exploring innovative materials and refining post-processing techniques to address these challenges. It paves the way for even more widespread adoption of prototype sheet metal in diverse applications.

A further increase in efficiency and precision is expected to be achieved through AI and machine learning integration in rapid prototyping. This technological convergence will position rapid prototyping companies as key players in shaping the future of sheet metal prototypes.

Conclusion

In conclusion, the synergy between rapid prototyping companies and the sheet metal fabrication industry has ushered in a new era of innovation and efficiency. The statistics speak volumes about the growing significance of rapid prototyping in producing prototype sheet metal components. As technology advances, we can expect further refinements and breakthroughs, solidifying rapid prototyping companies as driving forces behind the evolution of sheet metal prototypes in the manufacturing landscape.